- Tank Truck Equipment

- Service Station Equipment

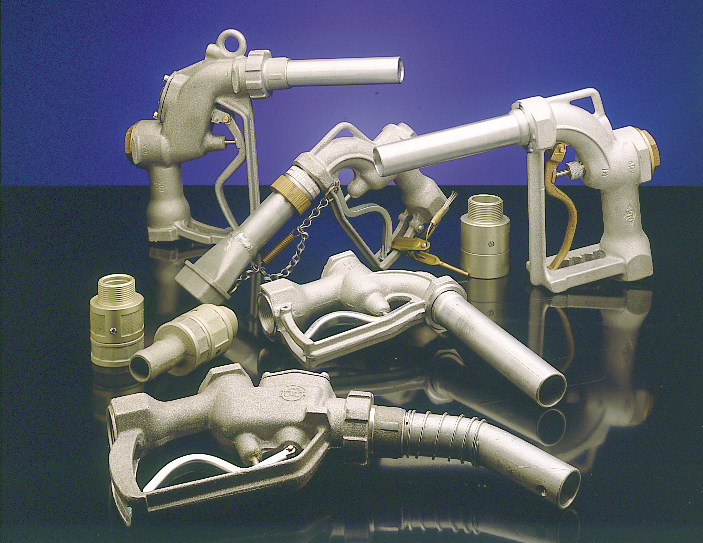

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

Tube Steady

| Order codes | Spares |

|

TS300 TD300A TS300D

|

|

APPLICATION

Dip and fill tubes form an integral part of each compartment in a road or storage tank. The FT300 filltubes are used where there is a requirement to top load.

The TS300 series tube steadies locate the dip and fill tubes on the tank floor and conform to AS2809.2.

FEATURES

• DT series dip tubes are made of extruded aluminium tube suitable for attachment to the FH series dip and fill hatches.

• The dip and fill tubes have a pressure equalising slot complete with an anti flash gauze in compliance with AS2809-2.

• The dip and fill tube steadies complete with striker pad are used to prevent movement of tubes when the vehicle is in motion or being filled.

• Only one weld position is required for the TS series tube steadies.

• The 45° slope at the end of the fill tube and the required clearance between each tube and the tank floor are an integral part of the casting on the TS300.

• Removal of dip and fill tubes can be achieved without the removal of the manway.

• The TS300D dip steady is available for customers who do not require a fill tube, such as for bottom loaded vehicles.

• The tube steadies may be fitted with a rubber bearing ring if required, to reduce tube vibration and wear.

SPECIFICATIONS

TS300 Dip and Fill Tube Steady

TS300A Dip and fill tube steady with seals

TS300D Dip Steady

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)