We've been serving Australian industries for nearly a century.

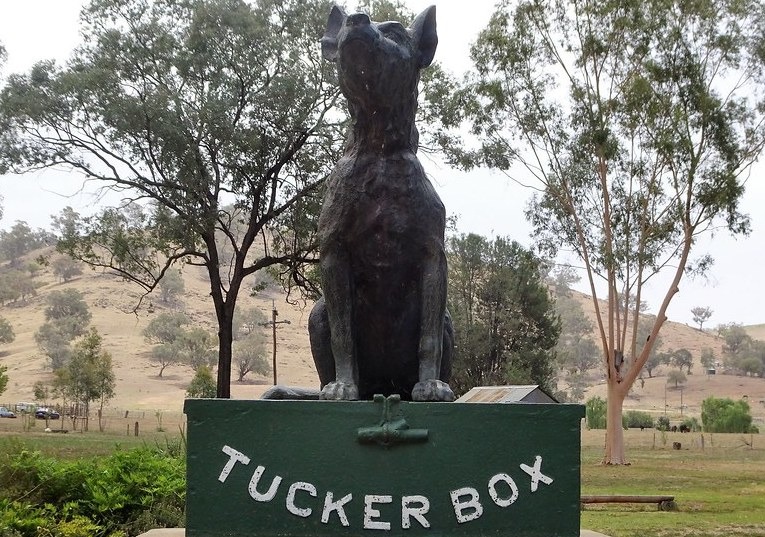

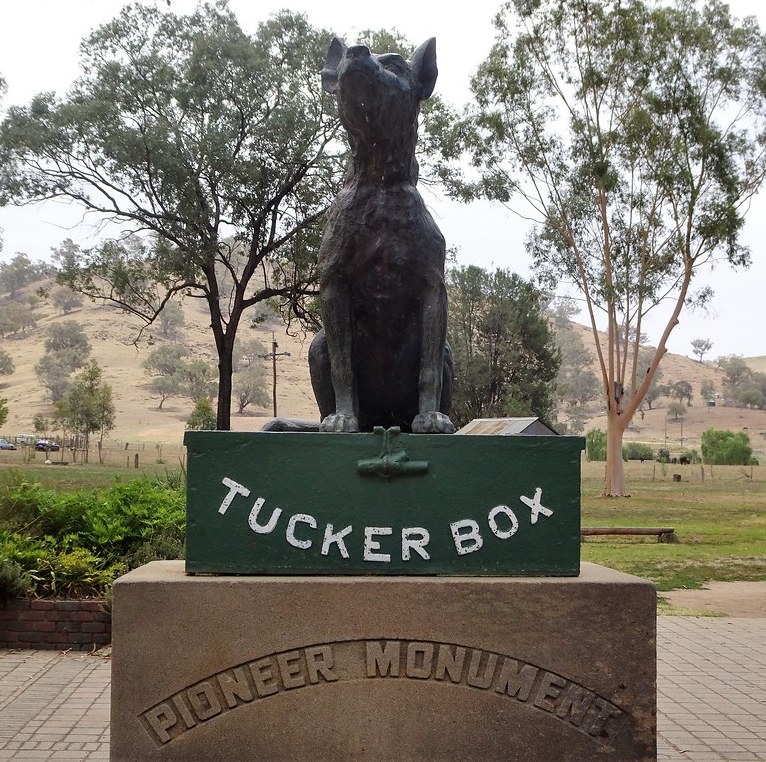

Treloar was originally founded in 1927 by the Oliver brothers as a foundry casting non-ferrous metals in Sydney. The foundry cast some historic monuments throughout the Hunter region, most notably the Hunter Valley Bollards and The Dog on the Tuckerbox monument which was erected near Gundagai in 1932 (pictured left). The monument was unveiled by Australian Prime Minister, Joe Lyons, in 1932 and is a loved tourist attraction today.

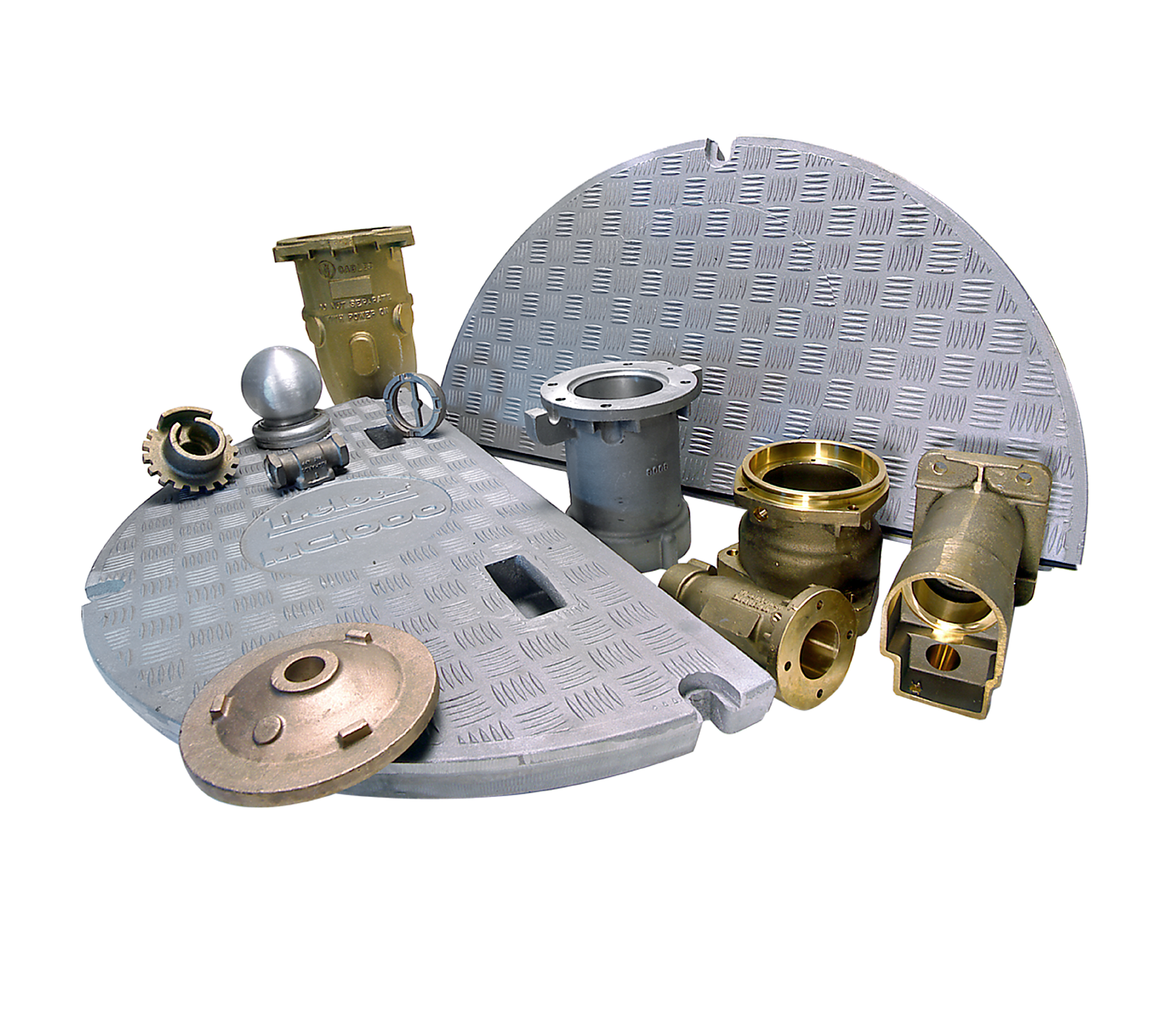

By the early 2000s, Treloar had become one of the leading foundries in Australia and our focus had shifted to mainly fluid transfer fittings. After many ups and downs and several strategic shifts, today, we have evolved into an industry-leading supplier of high-quality critical fluid handling products and services. Treloar is passionate about providing safe, dependable products that protect our customers and the environments they operate in. It’s that passion that has led to Treloar products being trusted by companies Australia-wide and internationally.

Treloar has a strong partnership with an Australian company that operates several manufacturing facilities internationally to produce our products. We source critical components locally and all final quality control, assembly and testing are conducted by specialists at our headquarters in Rutherford, NSW.

We’re a leader in critical fluid transfer system design because of our proven and dependable products, technical standards and long-term commitment to safety and quality. As part of this commitment, Treloar’s Engineering Department is responsible for the continuous improvement of current lines as well as the development of fit-for-purpose products and services customised to client needs. It’s this commitment that gives us the confidence to say we can solve any critical fluid handling challenge you send our way!

CUSTOMER SERVICE TEAM

Paul Walton

Engineering Manager

Jackeline Kress

Customer Service / Purchasing

Works in the division of Procurement and Customer Service.

Joined the Treloar team in 2004 as a Receptionist and transitioned to Sales in 2016.

Out of work Jackeline enjoys being engrossed in her garden, time devoted to close family and play times with her pet dog Ollie.

Jason Fuller

Customer Service / Dispatch

Customer service representative with over 20 years of sales experience ranging from speciality Trucks and cars to motorhomes and caravans

Jason joined Treloar in 2018, his favourite part of his job is Face to Face interaction with customers and always keen to learn and develop his knowledge.

He is a proud father of 1 son and 2 daughters and likes to go camping and fishing to unwind.

.png?width=217&height=65&name=Logo%20(2).png)