- Tank Truck Equipment

- Service Station Equipment

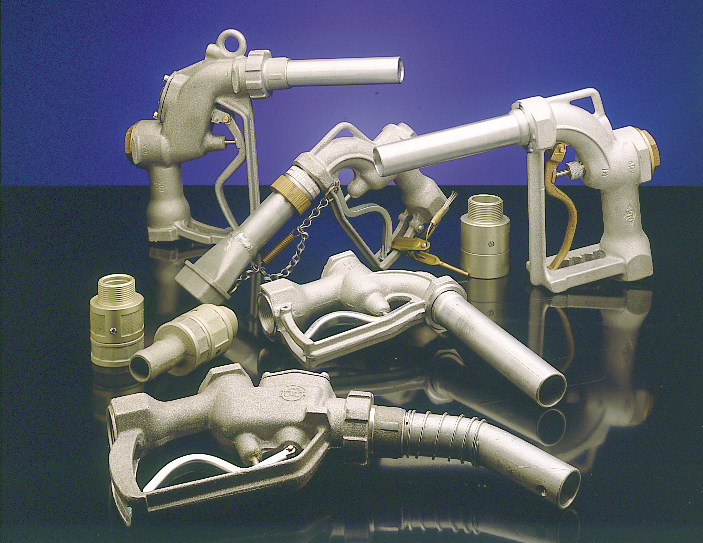

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

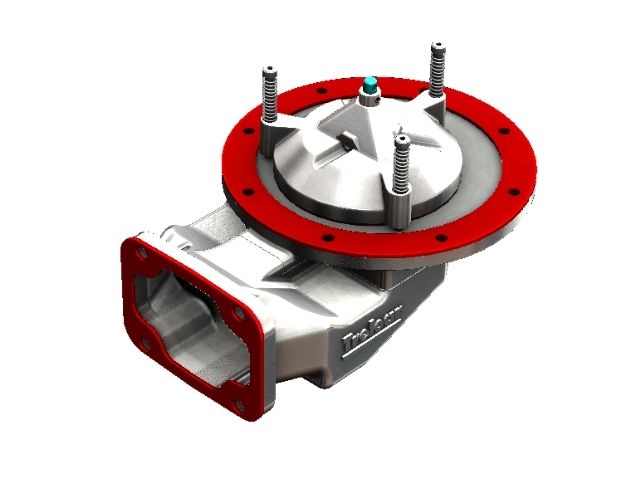

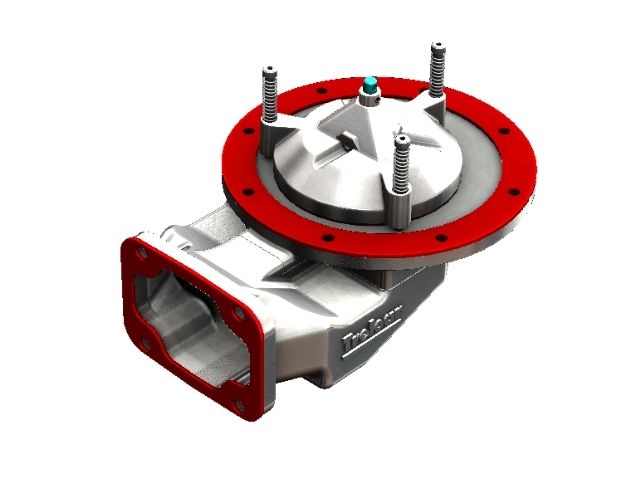

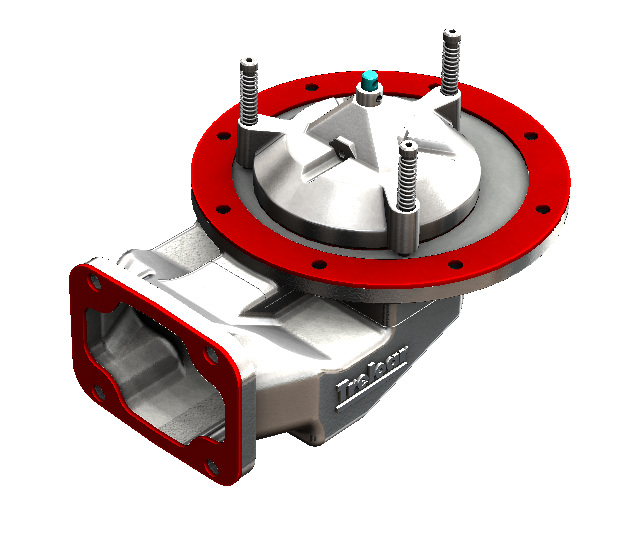

Internal Valve

| Order codes | Spares |

|

697J-125 C/W JACKING SCREW 697JC-125 CHEMICAL C/W JACKING SCREW 697M-125 C/W HANDLE 697MC-125 CHEMICAL C/W HANDLE

|

697RK; repair kit secondary poppet and bolts 697SK; seal kit 697J & 697M

|

APPLICATION

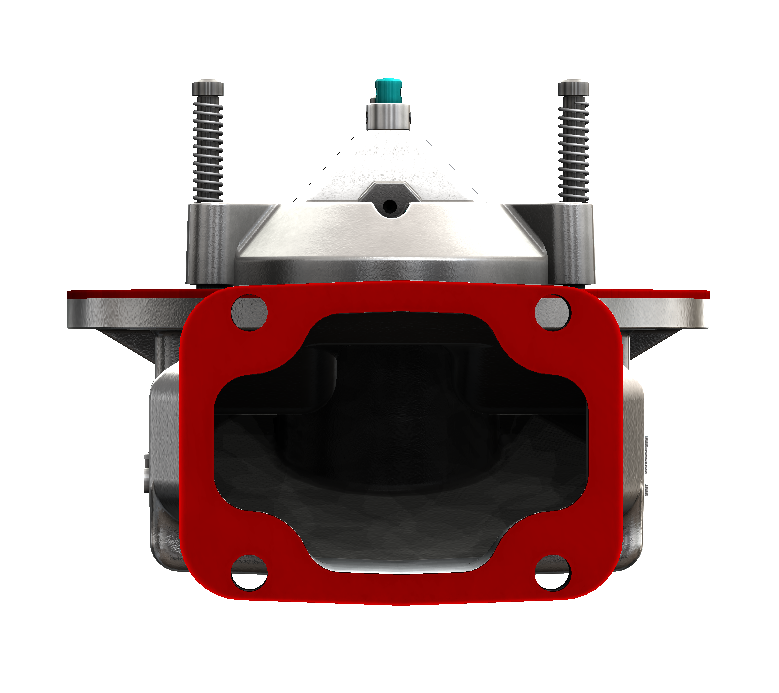

The 697 Series Internal Valve form the product inlet and outlet to each road tanker compartment. The valve operates within the tank barrel and has a cast shear groove on the valve body if the external pipework is damaged or torn away to ensure the valve remains closed.

If a pump is used to discharge product from the tanker, it is recommended that a top operator be used to actuate the valve.

FEATURES

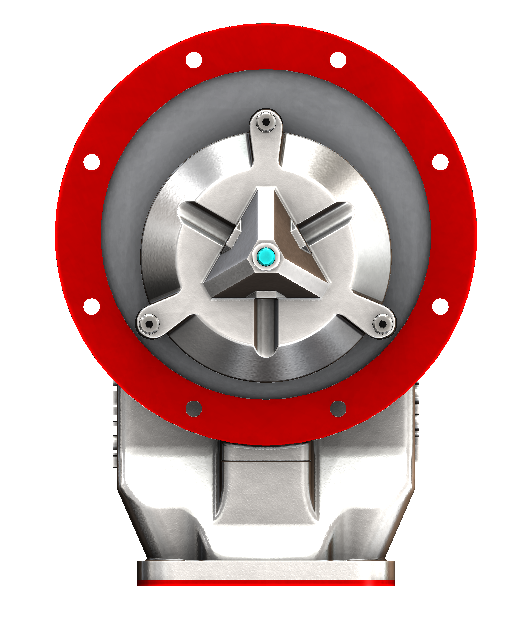

• Simple, direct push piston operation eliminates the need for diaphragms.

• The flange bolting patterns allows the valve to be retrofitted to existing tankers having similar flanges and mounting locations.

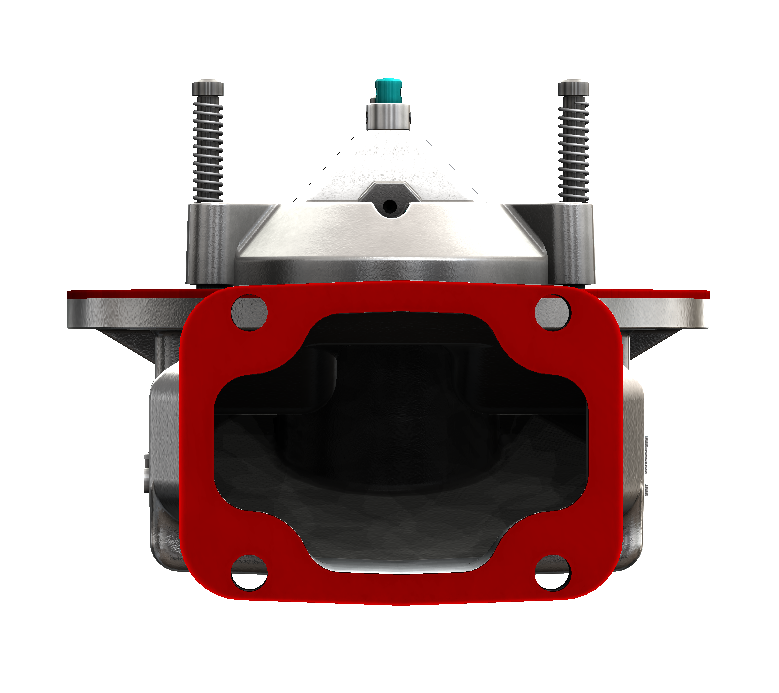

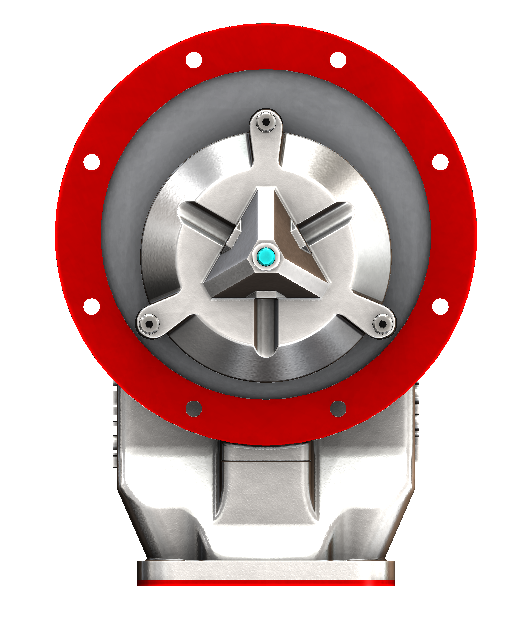

• The vertical lift poppet disc with specially designed flow contours evenly discharge product into the tank minimising unwanted upward spray thus eliminating the need for additional deflectors.

• Compact emergency override handle can be accessed easily, independent of valve orientation on the 697M model.

• The valve incorporates a 90° swivel elbow air fitting, allowing air hose connections from both sides.

• Reduced number of internal components promotes greater reliability and lower maintenance requirements.

• The 697 series valve has provision for both pneumatic bottom operation and top operation. A manual top operator can also be used to actuate the valve.

• The valve disc uses a tapered seat for consistent sealing.

• All dynamic seals are Viton.

• Valve may be removed from the outside - for servicing.

• Narrow body design accommodates tight piping constraints.

• Sequencing port available if desired.

SPECIFICATIONS

Tank flange mounting detail - 8 holes x ø10mm on 210mm PCD

Pipe flange mounting detail - 4 holes x ø12mm 98mm c/c horizontal x 84mm c/c vertical

Air Line fitting - 6mm

Min. air pressure requirement - 650kPa

Weight - 4.38kg

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)