- Tank Truck Equipment

- Service Station Equipment

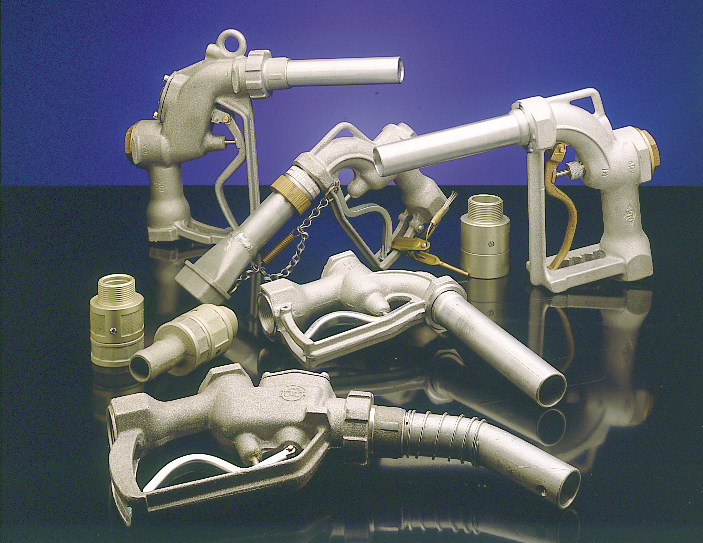

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

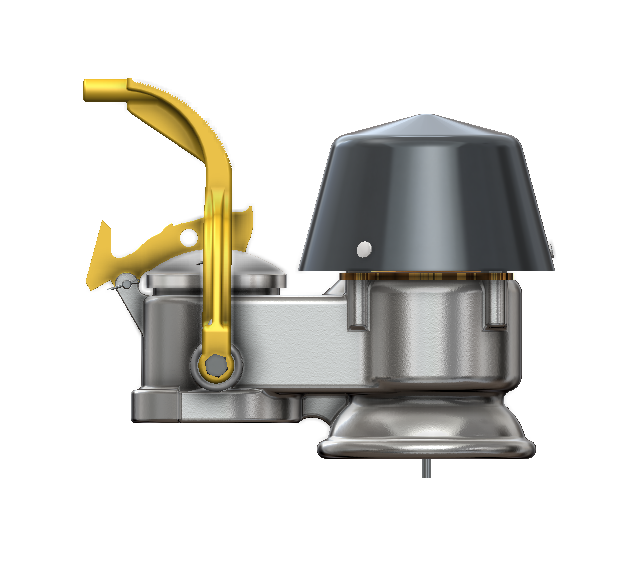

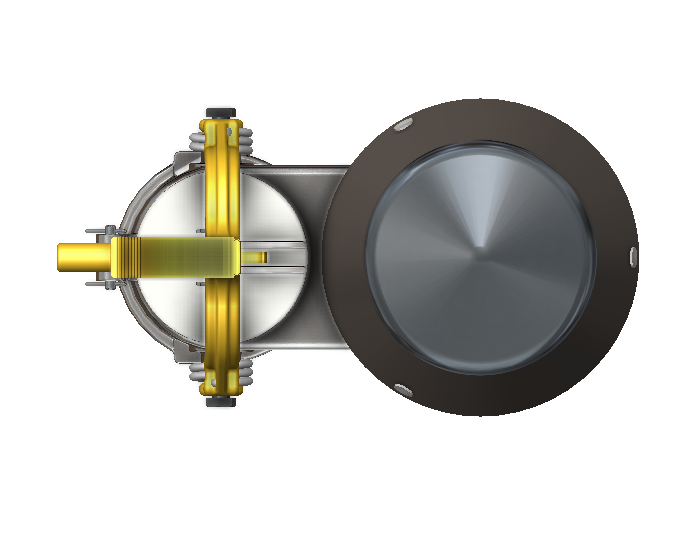

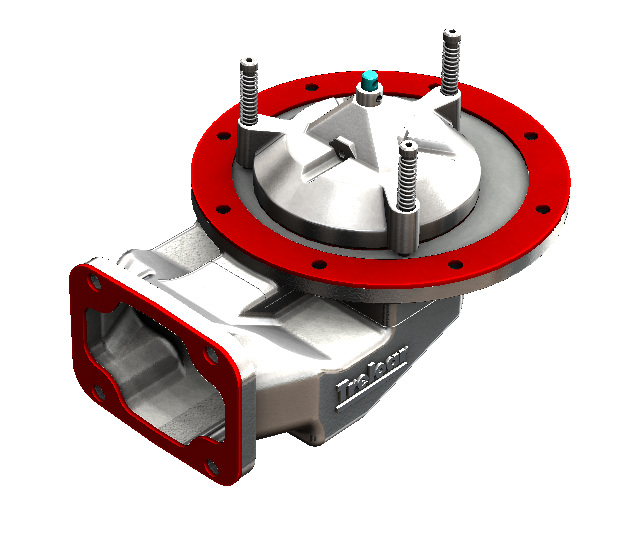

Pressure & Vacuum Vent

| Order codes | Spares | |

|

95U-50-3.5 95U-50-9.5 95U-50-10.5 95U-50-14 95U-50-17.5 95U-50-21 95U-50-35 95MU-50-3.5 95MU-50-9.5 95MU-50-10.5 95MU-50-14 95MU-50-17.5

|

95MU-50-21 95MU-50-35 95U-80-1 95U-80-7 95U-80-14 95U-80-17.5 95U-80-24 95MU-80-1 95MU-80-7 95MU-80-14 95MU-80-17.5 95MU-80-24

|

95UK-50: Repair Kit 95U/MU-50 95UK-80: Repair Kit 95UMU-80

|

APPLICATION

The Treloar 95 series pressure and vacuum vents are used on storage tanks for flammable liquids. The vents are designed to hold product within the storage tank at higher than atmospheric pressures, in doing so, restricting the evaporative losses of product. Vent specification is determined by tank design pressure, tank capacity, filling and emptying rates and type of product stored. These vents meet the requirements of API 2000 code as stipulated in AS1940-2004, Appendix I.

FEATURES

• Various standard pressure settings are available with each size of vent.

• Rust free aluminium, stainless and Bronze parts

• Simple and easy to maintain weight actuation system

• Vents are available with a dip point or gauge hatch (refer 95U).

• Spring loaded hatch automatically reseals on release of operator yoke.

• The emergency vent must be 7kPa above the setting of the P&V vent

SPECIFICATIONS

Vents available in 50mm and 80mm

Vents are specified in accordance with AS1940

Connections: Standard DN50 and DN80 BSP female, flanged adaptors are available to suit ANSI#150 or #300 flanges.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)