- Tank Truck Equipment

- Service Station Equipment

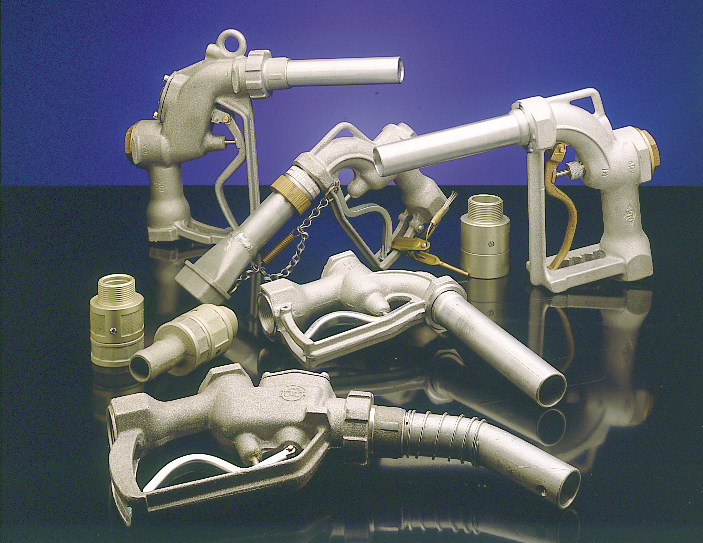

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

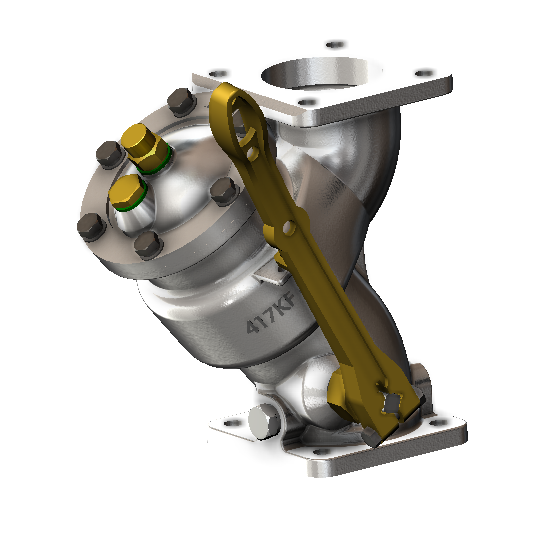

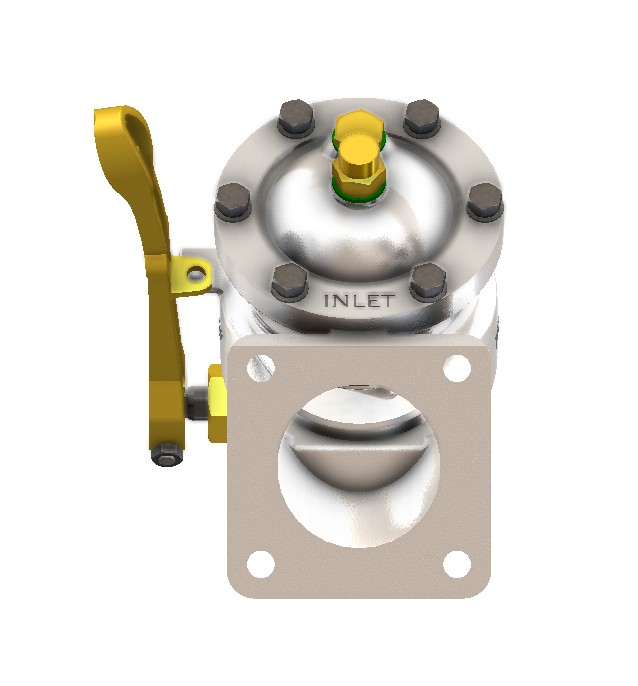

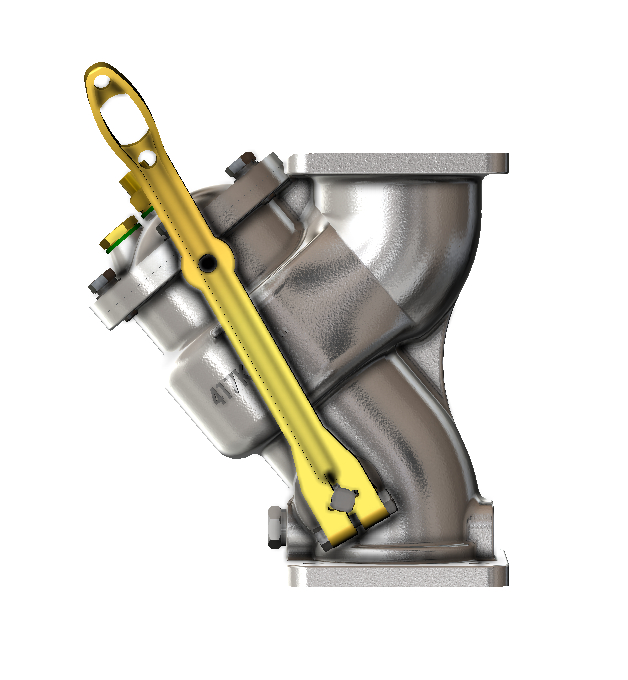

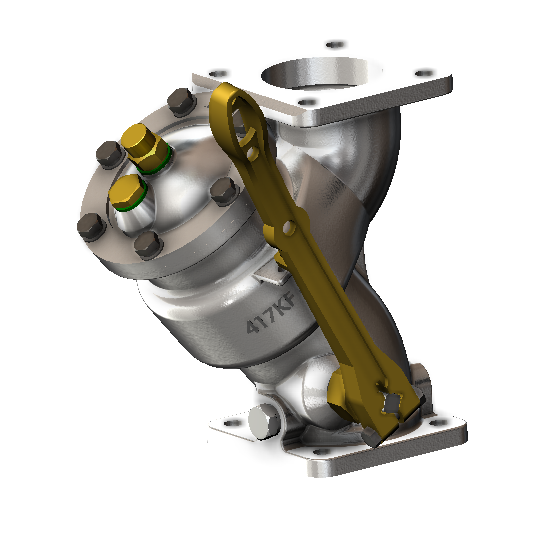

Shockless Closing Loading/Deadman Valves

| Order codes | Spares |

|

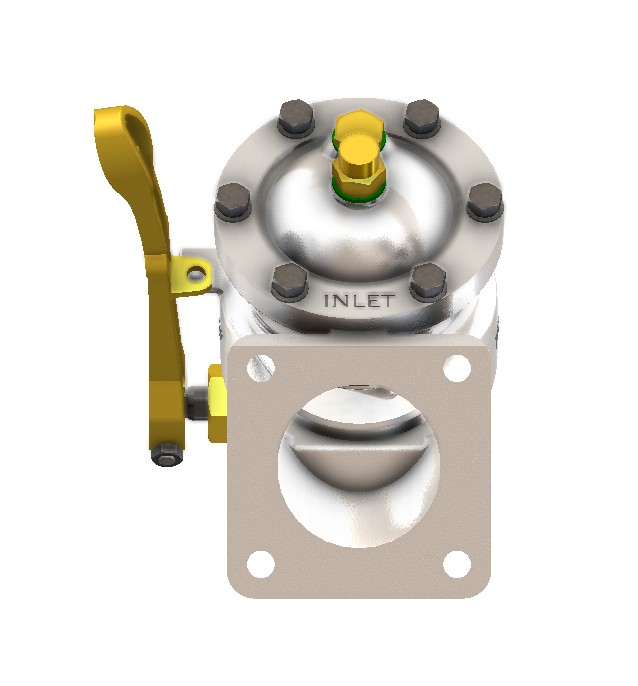

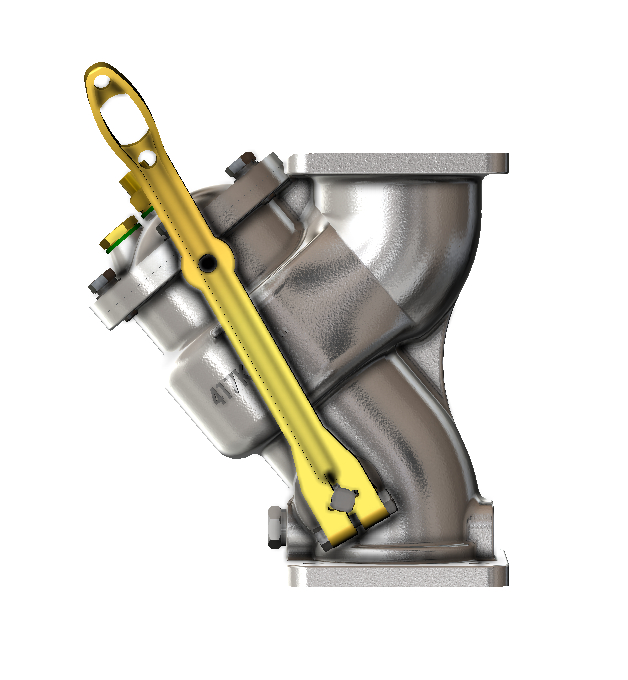

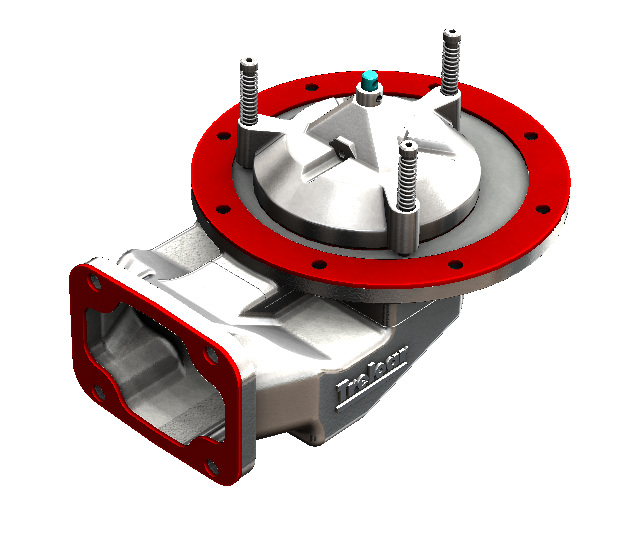

417KF-80

|

APPLICATION

Treloar-OPW loading valves are used for loading liquid products from a fixed loading point into portable tanks or tank truck compartments by the top loading method. They are particularly advantageous when used in conjunction with Treloar-OPW loading assemblies.

The 417KF valve is equally at home when used with hose type loading assemblies.

The reasons why it is so beneficial in these applications is due to its inherent design, which allows for final slow and shockless closing of the main valve onto its seat. This eliminates extreme line shock affecting upstream equipment like meters, pumps, filters etc. Also, because of its unique dashpot control, air cannot become trapped in the dashpot so the valve cannot “pop open” after closure and closed valve security is positive

FEATURES

• Deadman Operation - Spring return handle requires operator presence.

• Shut Down - The 417KF incorporates two separate externally adjustable closure rates. This allows fast initial closure on high flow rates and soft final shut down with minimum line hammer and associated damage to pumps and meters. The closure rates are extremely easy to field adjust to suit various flow rates without the need to dismantle.

• First Stage - First stage closure controls the overall speed of valve shutdown. It utilises the cap bleed valve and adjustable piston stroke valve (refer Installation Sheet)

Second Stage - Variable control over “slow” final closure rate is by a simple needle valve screw to prevent shock.

• Air Traps - The 417KF can be installed in the vertical or inverted position, allowing the operator handle to be operated by lifting or pulling.

• Operating Cam - The 417KF operating cam acts upon a roller, this minimises operator effort and removes wear on the cam resulting in “jerky” operation and increased maintenance.

SPECIFICATIONS

Flange Details: 80mm - Square Flange - 134 square with 4x14mm diameter holes drilled on 139.7mm P.C.D

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)