- Tank Truck Equipment

- Service Station Equipment

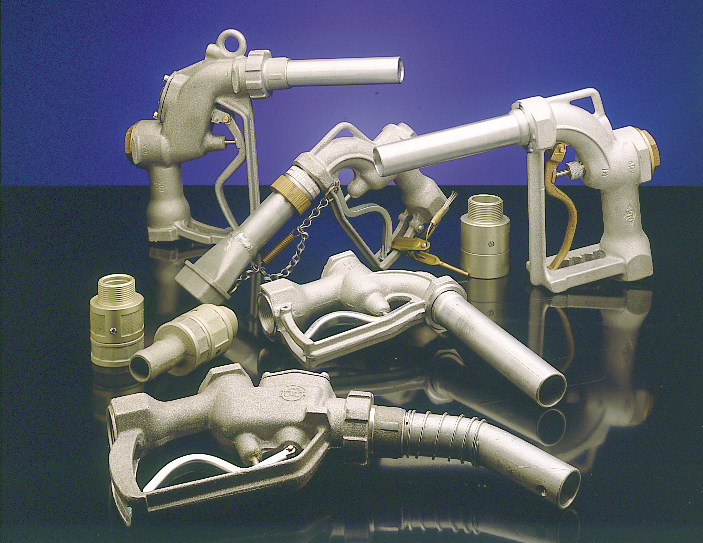

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

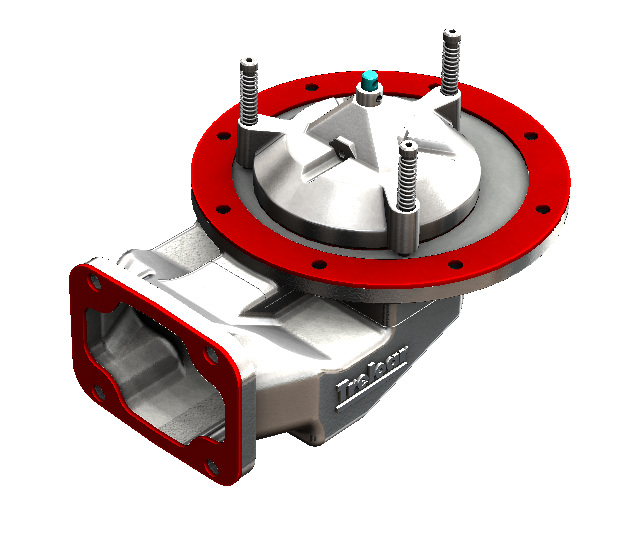

- Valve Products

- Projects

.jpg)

.jpg)

Reconnectable Breakaway

| Order codes | Spares |

|

66REC-20x20

|

|

RECONNECTABLE BREAKAWAY VALVE FOR FUEL APPLICATION

The OPW 66REC is the first dry reconnectable breakaway for the conventional dispensing market. It is designed to be installed on fuel dispensing hoses and will separate when subjected to a designated pull force. The dual valves seat automatically stops the flow of fuel and limits any fuel spillage, while protecting the dispensing equipment. The two halves are easily reconnected and seal tightly on an 0-ring before the poppet stems engage to open the valve.

For proper operation of the breakaway valve fuel on high-hanging hoses, the OPW 66REC must always be installed with a “straightening” hose with a minimum length of 230mm.

FEATURES

• Pull force - the 66REC will breakaway with a pull force of no more than 113kg.

• Unique double poppet design - features low pressure drop.

• Coupling halves - protected by proven plastic sleeves.

• Easily reconnected - just “push and twist” until you hear the audible click, signifying the unit has been correctly reconnected. • Reconnection force approximately 7kg.

• Line Shock - the 66REC is able to absorb the effects of normal line shock through the unique design of the disconnecting features.

• The breakaway valve fuel may be reconnected under wet or dry hose conditions.

SPECIFICATIONS

Max Static Pressure: 350kPa (50psi)

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)