- Tank Truck Equipment

- Service Station Equipment

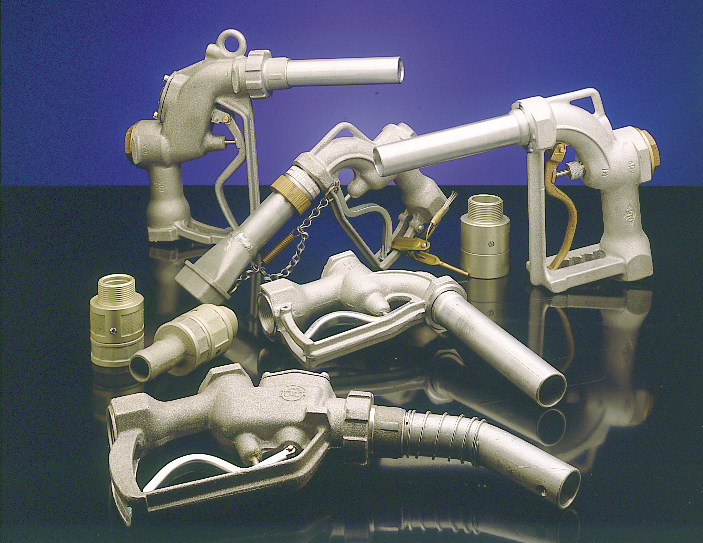

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

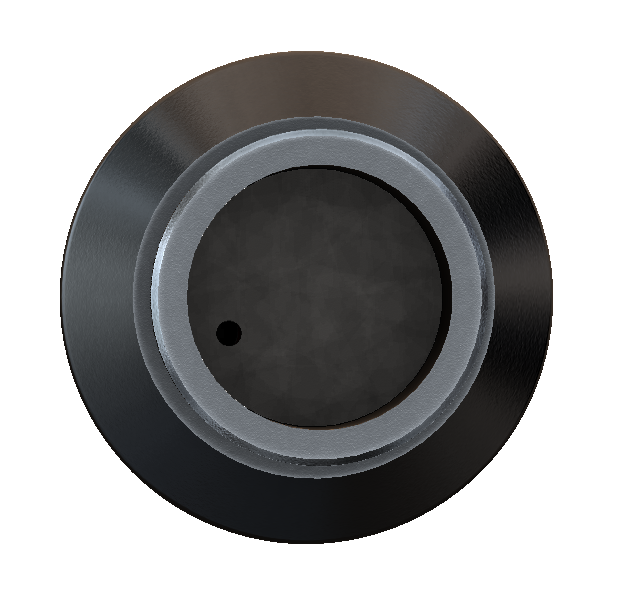

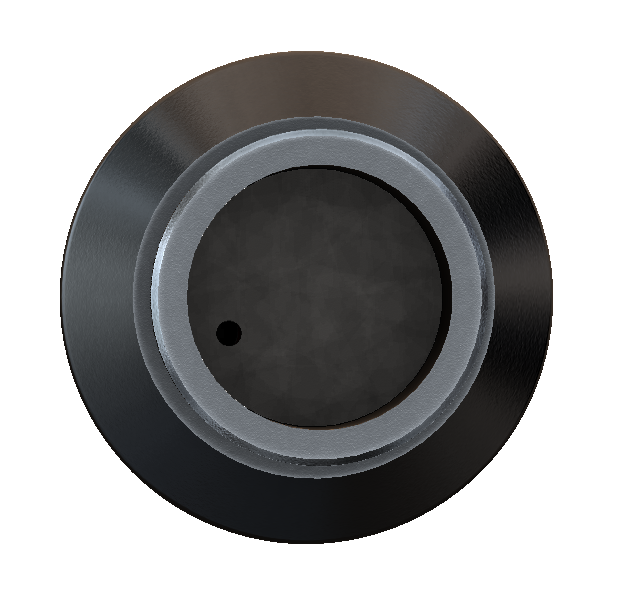

Pressure and Vacuum Vent

| Order codes | Spares |

|

PV007 PV007L PV304/1 DPV217

|

(Interchangeable with Liquip PVV104) Service Exchange available, due to testing and regulatory requirments this product must be returned to treloar for service

|

PRESSURE AND VACUUM VENT APPLICATION

The Treloar PV007 series pressure vacuum vent (Interchangeable with Liquip PVV104) features a high flow vent path for pressure and vacuum relief on road tanker compartments. The vent incorporates a free vent, rollover shut-off vacuum pressure release valve and complies with the requirements of AS2809.2 - 1999 for small compartment tanks.

FEATURES

The PV007 vents will vent freely up to the pressure or vacuum settings after, which the pressure or vacuum pressure release valve will open.

• The clear area through the pressure and vacuum vents exceed the minimum requirements of the standard.

• At an angle exceeding 60°, the rollover valve will cause the vent to shut-off completely, preventing product loss from the vent.

• Metal to viton seats on the pressure and vacuum valves reduce maintenance costs.

• The exit of the vent is covered with a 30 mesh antiflash gauze.

* available with various adaptors to suit older Treloar or other brand hatches

SPECIFICATIONS

PV Vent pressure relief = 16 ± 1 kPa

PV Vent vacuum relief = -2 ± 1 kPa

Weight = 1.34 kg

Service Exchange:

Due to testing and regulatory requirements, the Treloar PV007 series pressure and vacuum vents are part of a service exchange program. This means you can return a used vent to Treloar, and we will replace it with a serviced and certified unit. This ensures your vents continue to meet the required safety standards.

Pressure and Vacuum Vent Application

The Treloar PV007 series pressure vacuum vent is designed for use on road tanker compartments. It features a high flow vent path for efficient pressure and vacuum relief. The vent incorporates a free vent mechanism that allows air to enter or exit the tank at atmospheric pressure. Additionally, it includes a rollover shut-off pressure vacuum valve that automatically closes in case of a rollover accident, preventing product loss. The PV007 series complies with the requirements of AS2809.2 - 1999 for small compartment tanks.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)