- Tank Truck Equipment

- Service Station Equipment

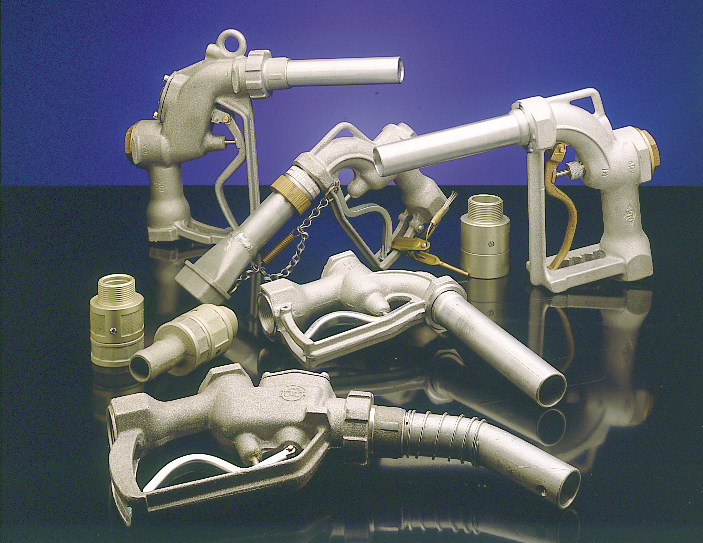

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

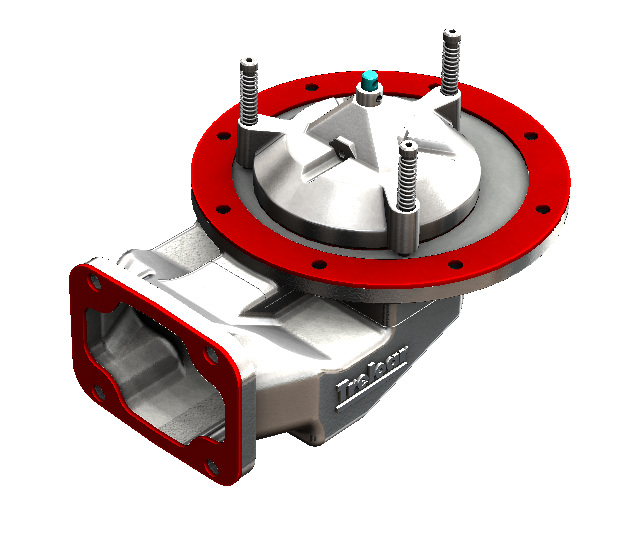

- Valve Products

- Projects

High Performance Manual Nozzle

| Order codes | Spares |

|

Consult

|

Consult

|

APPLICATION

Offered in a large number of different versions, ARTA Filler Nozzles are suitable for filling almost all types of containers used in the industrial sector. We offer filler nozzles made from different materials to suit different types of media. Among other applications, they can be used to for chemicals, aggressive media or solvents. For example, the smallest and most convenient version, the ZV-DN 12, is used for filling and emptying small containers, as well as for additives, sampling and laboratory applications. In order to ensure precise filling or emptying, we offer four special outlet tube types for the ARTA ZV-DN 12. The ergonomically optimized hand lever of the ZV-DN 12 allows precision handling of smaller quantities. The DN 20/25/32 nominal diameter automatic and manual filler nozzles are ideal for barrel and canister operations. For use on large drums and containers, we recommend the high-performance filler nozzles ZV-FIXOMAT DN 50 and AZV DN 50, with integrated swivel joints.

FEATURES

• Safe and reliable closure

If there are fluctuations in the operating pressure and the pressure increases unintentionally, the intelligent design of ARTA Filling Nozzles makes certain that the nozzles go through the closing procedure without problems. The nozzles secure the media in the line, ensuring the safety of both the environment and the user.

• AZV® automatic closing process

Once the desired level is reached, the AZV Filler Nozzle registers the change in flow pressure and stops automatically.

• Optimized level

ARTA Filler Nozzles reduce foaming to a minimum, enabling maximum fill levels to be achieved.

• Ease of use

A high degree of user-friendliness characterizes ARTA Filler Nozzles. They can also be used with one hand while wearing protective gloves.

• No release of harmful gases

The formation of harmful gases may occur when filling with some liquids, which can harm both the user and the environment. For these circumstances, we offer gas recirculation systems. When combined with an ARTA Filler Nozzle, this solution prevents releasing the gas into the environment.

• Fully verified by international certification entities

ARTA Filler Nozzles are safety-certified worldwide by global assessment and approval. Because of this consistent standing, no safety-related reservations regarding its use exist.

SPECIFICATIONS

Sizes: DN 12 (1/2“) to DN 50 (2“)

Flow rating: 50 l/min to 400 l/min

Operating pressure: PN 3 to PN 6

Nominal pressure: 10 bar

Body material: Stainless Steel 1.4571 (316Ti)

Sealing: PTFE/PFE

Connections: G 3/4″ IG; G 1″ AG bis G 2″ AG others on request

Conformities: 2014/68/EU PED, 2014/34/EU ATEX, EN14432, 21 CRF Part 11, USP Code 6

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)