- Tank Truck Equipment

- Service Station Equipment

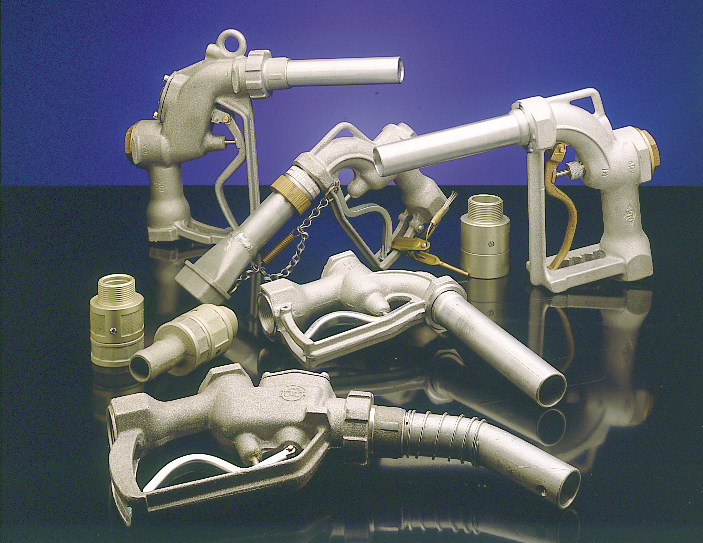

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

Four Signal Tank Alarm

| Order codes | Spares |

|

444TA-0100 44TA-LLFS 30-3221-1A 30-3221-1B

|

APPLICATION

The OPW 444TA monitors the required high level and interstitial space for all above ground storage tanks PLUS features a remote output switch for a secondary signal device, i.e. bull horn or signal strobe located within an occupied structure.

NOTE: Output Switch will not power another device.

The OPW 444TA AST Remote Four Signal Tank Alarm is designed to sense up to four different liquid levels or other signals using just one device. Both audible and visual indicators are used to ensure reliable notifications.

FEATURES

• Audible Alarm – Sounds a 90-decibel alarm at 4 feet away.

• Visual Notifications – Red alarm light will flash during use for notification to the user. Low battery light indicates when battery needs replaced.

• Intrinsically Safe – Complies with ANSI/UL 913 for Class I, Division 1 & 2 for Groups C & D hazardous locations.

• Long Life Lithium Battery – Self powered by a Lithium battery which includes a 10-year shelf life to ensure peace of mind for the owner.

• Up to four alarm signals – That can be used for high or low liquid level sensing, interstitial monitoring, and/or other signals in one to four separate tanks.

• Relay Option – Trigger another alarm, pump, switch, or other device from this alarm unit.

• Self-powered – Lithium battery with a 10-year shelf life for long service life.

• Audible Alarm – Sounds a 90-decibel alarm at 4 feet away.

• Float Switch Sub-Assembly – Uses all Stainless Steel construction that allows use in an array of fluid applications.

• Product /Alarm Identification Label – Located on top of the alarm for quick and easy identification, allowing you to correspond alarms to signals. Label has a protective covering.

• Intrinsically Safe – Complies with ANSI/UL 913 for Class 1, Division 1 & 2 for Groups C & D hazardous locations.

• Cold Weather Resistant – All components are safe for temperatures down to -40ºF operation (and up to 120º F).

SPECIFICATIONS

Enclosure: Polybutylene Terephthalate Wire

Grommet: Nylon w/ Buna Seal

Float Switch: Closed Cell Buna Float & Stainless

Steel Rod Pipe: Stainless Steel

444TA-0100 4 Signal High Level Tank Alarm - Battery op -Diesel Only

*44TA-LLFS 36” Probe/Float Sub Assy 30-3221-1 Single level sump sensor

30-3221-1A Interstitial Level Sensor (Non metallic)

30-3221-1B Interstitial Level Sensor (Brass) PRODUCT IDENTIFICATION

*NOTE: The complete unit requires both Probe and Alarm components as listed above

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)