- Tank Truck Equipment

- Service Station Equipment

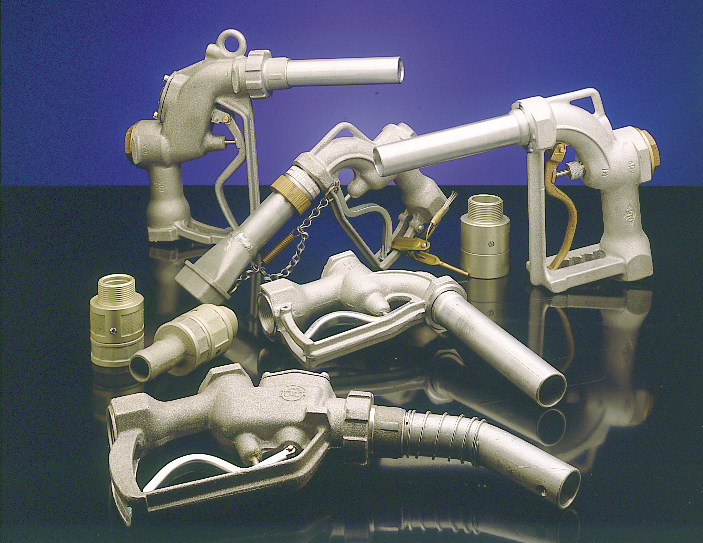

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

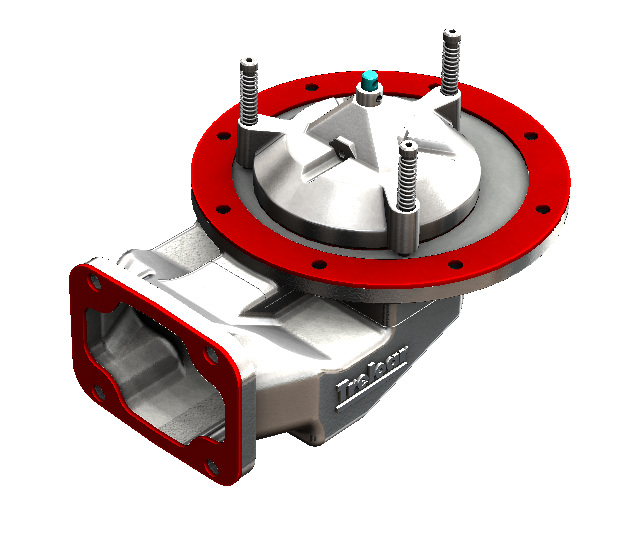

Epsilon Dry-break

| Order codes | Spares |

|

See data sheet

|

|

APPLICATION

The EPSILON™ coupling system is designed to prevent chemical spills and reduce fugitive emissions of volatile organic compounds (VOC’s), particularly in the process facility and during transfer to and from truck tanks and railroad tank cars.

During in-plant chemical transfers, EPSILON™ Chemical Containment System will provide your plant with process flexibility while also improving operator safety and enhancing environmental compliance and reducing overall capital expenditures and operating costs.

FEATURES

EPSILON™ is a low spill coupling, based on a double ball valve system integrating a sophisticated safety design in sizes of 1”, 2” and 3”. The design is constructed to handle a pressure of 25 Bar and temperature up to 240°C and is available with end connections complying to DIN and ANSI standards.

All wetted materials are 316 stainless steel (1.4401) with TFM or PFA seals. Hastelloy® C is also available for use with more aggressive fluids.

Beyond the common advantages of a ball valve design, EPSILON™ provides for flow through an unrestricted flow path and double shut off reliability in the coupling connection.

SPECIFICATIONS

SAFETY:

EPSILON™ coupling is equipped with safety interlocks, which force the valves to open and close only with a deliberate action, preventing accidental opening of the valve.

ENVIRONMENT:

EPSILON™ is a low spill system, specified to less than 1 ml spillage for the 2” coupling (2000 cycles test average 0.6 ml) and less than 0.7 ml for the 1” coupling.

MAINTENANCE:

EPSILON™ was not only engineered for easy operations, but also for quick replacement of the transfer seal without any lockout. No special tools are required for replacement of seals.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)