- Tank Truck Equipment

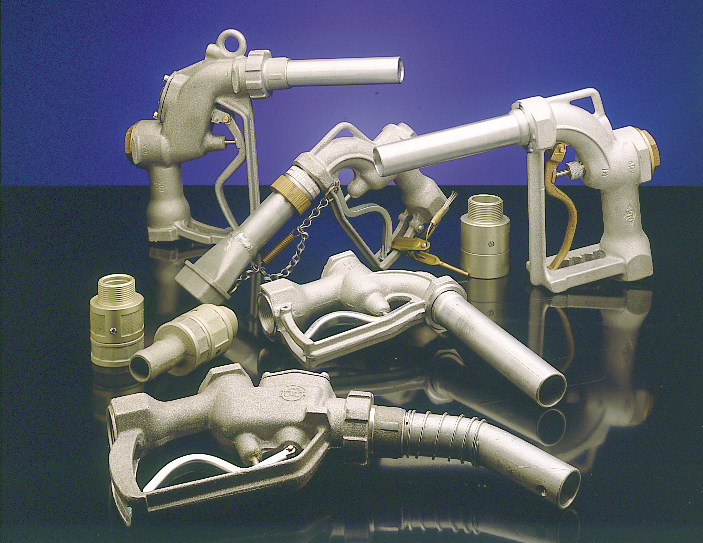

- Service Station Equipment

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

Engineered Dry Breaks (ASK-C)

| Order codes | Spares |

|

ASK-C ASK-TT ASK-CI ASK-GI ASK-API ASK-KS-HD ASK-CP ASK-FD ASK-HD |

Fully serviceable, kits available - call for details

|

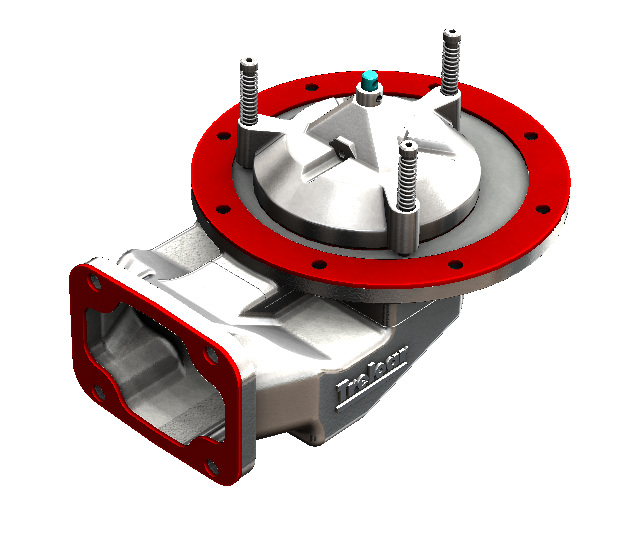

APPLICATION

The ASK®-C Dry Coupling transports liquid and gaseous media in suction or pressure lines in a spill-free, safe and environmentally friendly manner. It facilitates the quick connection and disconnection of filled hose lines and pipelines under operating pressure. Its integrated swivel minimizes mechanical wear, ensuring long-lasting use.

The ASK®-C Dry Break has been used successfully for over 50 years, which demonstrates its high level of maturity. Over the decades, we have continued to develop the coupling with the aid of the latest technological knowledge, making it a unique premium product.

FEATURES

Coupling and uncoupling the ASK Dry Break is quick and easy. In order to connect the coupling, place the female coupler on top of the male adaptor. By applying a single, continuous rotating motion, the coupling is first sealed and then its valves are opened. This keeps the transported media safely inside the line, without spillage.

Disconnection of the ASK®-C is accomplished in reverse order. The valves in the two halves of the coupling close automatically, preventing any loss of transported media. The male side normally stays on the system, and its valve remains securely closed until the next coupling process.

Spill-free & safe:

The ASK®-C couplings ensure spill-free coupling and uncoupling, without exposing either the user or the environment to the transported product.

Fast loading processes:

You can also uncouple the ASK®-C when a line is still filled, which greatly speeds up the loading process. The simple coupling operation also minimizes the time required to make a connection. This is significantly enhanced by the ergonomically optimized hand wheel, creating a much simpler operation, in comparison with a conventional grab handle.

Maximum flow:

We determined the flow-optimized design of the ASK®-C by using the finite element method (FEM), validated by flow tests. The result of this is that pressure loss is minimized and the Dry Break Coupling provides maximum delivery flow.

Integrated swivel joint:

The integrated swivel joint on the female side of the Dry Break reduces mechanical stress and prevents torsion stress in the pipe. Additionally, the high-quality design of the Dry Break ensures a permanently smooth rotation of the swivel joint. The ASK®-C therefore requires very little maintenance.

Greater safety with the ARTA pin:

The ARTA pin supplies yet another safety feature. It is located on the female side of the Dry Break and engages in the male adaptor to prevent the unintentional release of the coupling.

Error-free coupling using mechanical lockout:

We offer the option of a mechanical lockout for ARTA Dry Break couplings. This prevents accidental coupling to a connector carrying a different substance than intended, and thereby precludes mixing the transported products in error.

Fully verified by international certification entities:

The ASK®-C is a globally approved safety coupling that has been certified by recognized international approval entities and there are no reservations for its use in various safety-related applications.

SPECIFICATIONS

Sizes: DN15 (1/2“) bis DN200 (8“)

Pressure rating: PN16 (232psi) bis PN40 (580psi)

Temperature range: -55°C (-67°F) bis +200°C (+392°F)

Body material: Stainless steel 1.4301/1.4404/1.4571, Hastelloy®

Sealing: PFTE, EPDM, Viton® and other seals on request.

Connections: Thread-NPT, BSP, ISO; Flanges-ANSI, ISO; others on request

Conformities: 2014/68/EU Druckgeräterichtlinie, 2014/34/EU ATEX, EN14432, 21 CRF Part 11, USP Code 6

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)