- Tank Truck Equipment

- Service Station Equipment

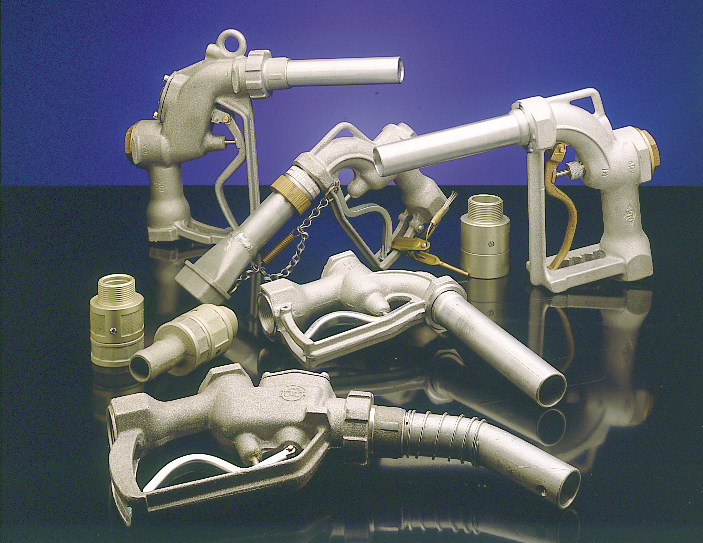

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

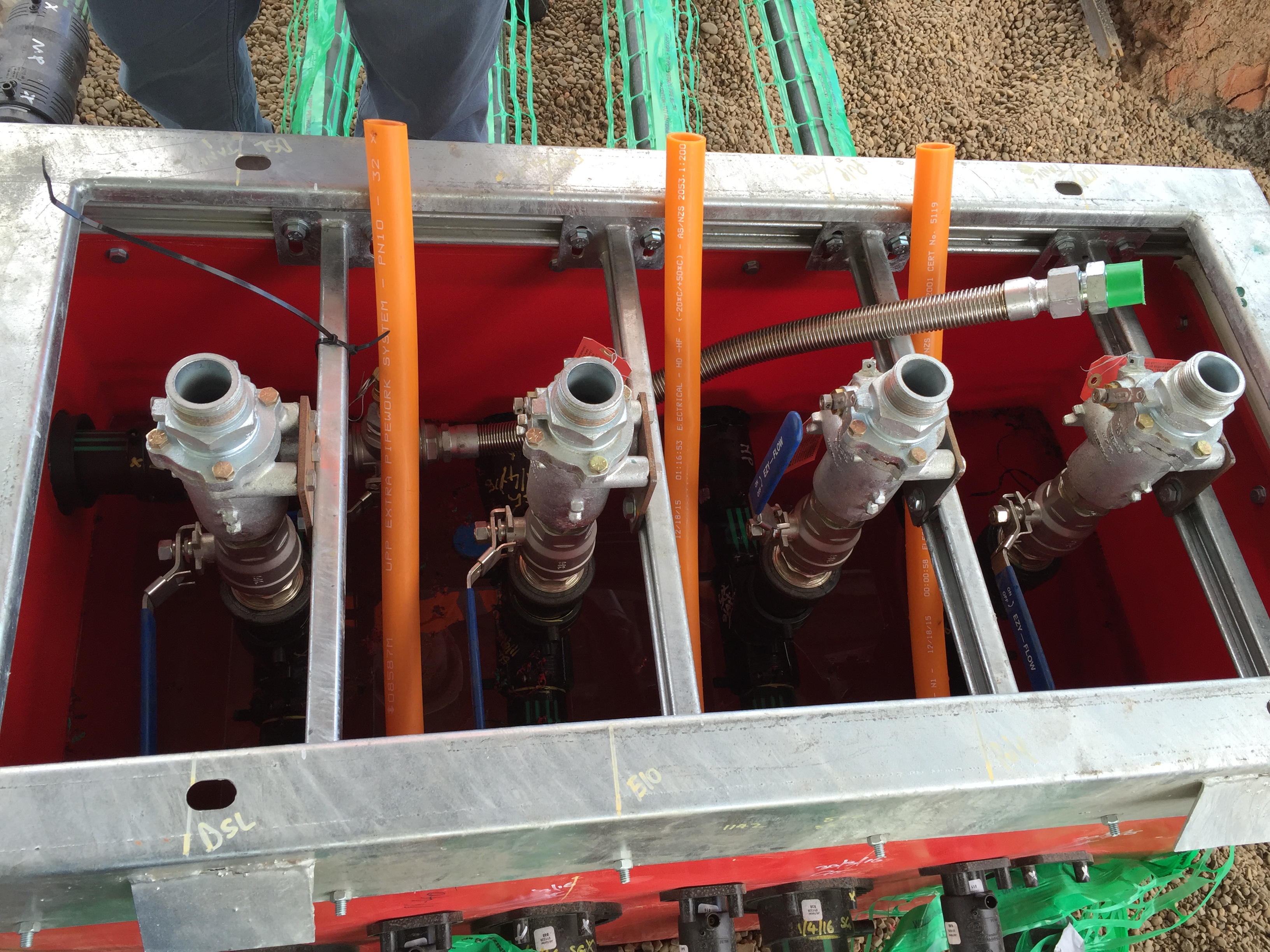

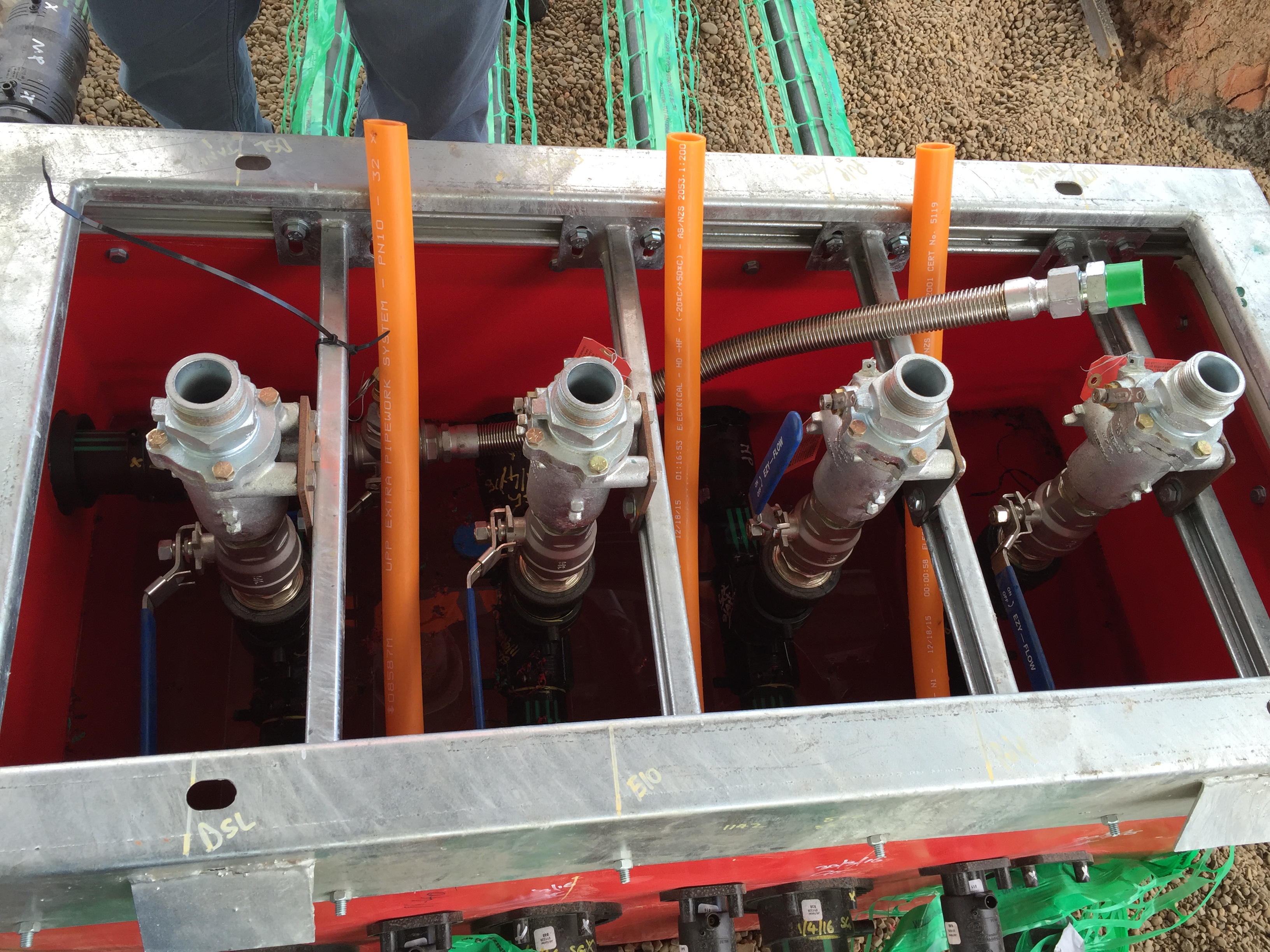

- Projects

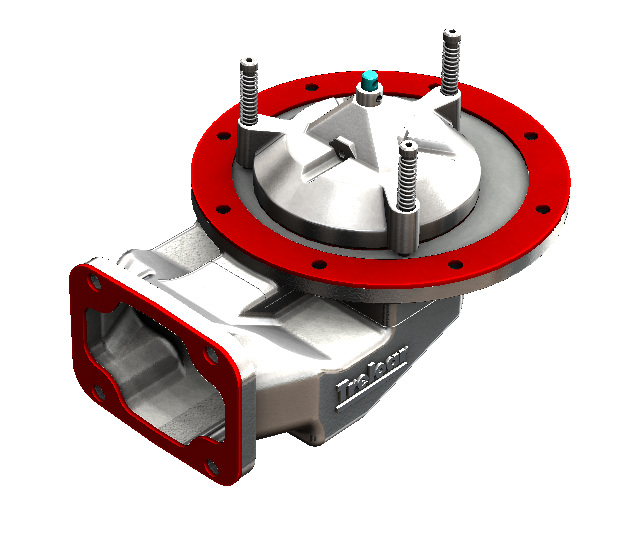

Emergency Shut-Off Valve

| Order codes | Spares |

|

10BM-40-BSP 10BM-50-BSP 10BHM-40-BSP 10BHM-50-BSP 10BM-40-NPT 10BM-50-NPT 10BHM-40-NPT 10BHM-50-NPT

|

Replacement parts available, contact us for details

|

APPLICATION

The emergency shut-off valve is designed to be mounted in the fuel dispensing lines of pressure systems at the island level. In the event the dispenser is dislocated or overturned, the valve is designed to break at the shear groove. This releases the hold open linkage and allows the main poppet to close, stopping the flow of product from the underground tank.

The dual poppet version has an additional feature: in the event that the valve shears the secondary poppet closes and limits spillage from the dispenser side of the valve. The fusable link also closes off the flow in the case of fire by breaking and shutting the poppet. Various sizes and models available to suit all service station requirements

FEATURES

• The sealing surface in the top assembly assures a new sealing surface if a top is replaced, improving performance and extending service life.

• The 10B series valves can be shut off by releasing the hub link during pump repair or removal - this means less down time, the poppet is easy to manually reset.

• When the 10B valve is open, the poppet is out of the flow area giving straight through free flow. There is low pressure drop.

• The 10B series has a built in air test port. This allows pneumatic testing of the entire pumping system without breaking the line after installation is complete.

• Fusible link releases in the event of fire, allowing the valve to automatically close, thus reducing the fire hazard.

• Listed by Underwriters Laboratory Inc. for gasoline blends up to 100% methanol.

• Black or Zn coating provides extra corrosion protection and easy identification.

SPECIFICATIONS

Inlet/Outlet: Thread sizes 40mm and 50mm BSP standard (NPT avail.)

Max Operating Pressure: 50 psi (345 kPa)

At least once a year, manually open and close the valve several times to prevent gum deposits, build-up and/or other conditions that may affect the operation of the valve.

These requirements are stated in the installation instructions on all 10B Series Emergency Shut-off valves.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)