- Tank Truck Equipment

- Service Station Equipment

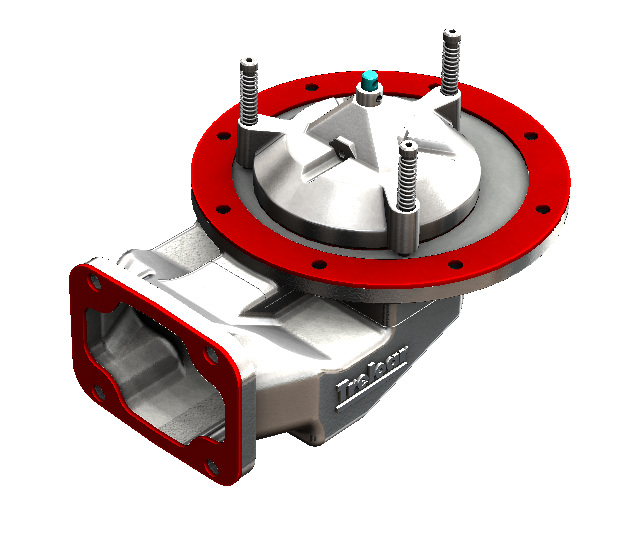

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

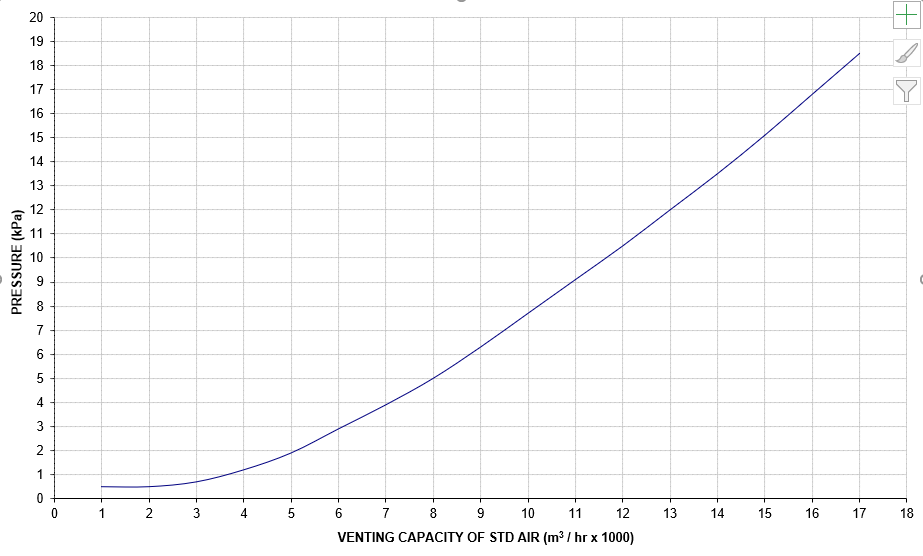

Emergency Pressure Relief Vent

| Order codes | Spares |

|

202F-200-17.5 202F-200-24

|

R015681-000 : 202F-200-17.5kPa SERVICE KIT, Incl. (Break link 2 Notch, O-ring, Circlips x 2, Roll pin) |

APPLICATION

We have a new break link to replace the carbon Pin on our 17.5kPa model, this simplifies installation and improves accuracy of relief pressure. Our new service kits are also now available so the vents can be reset after scheduled maintenance. The Treloar 202F emergency vents are used on above ground bulk plant and storage tanks. The emergency vent is an auxiliary to a free vent or pressure-vacuum vent, such as the Treloar 95U. It acts to relieve excess internal pressure created by overheating, fire and over-pumping etc. These vents meet the requirements of API 2000 code as stipulated in AS 1940.

FEATURES

• The 202F vent, unlike other emergency vents, will show a failure mode, thus indicating that there are design or operational problems associated with the storage facility.

• The 202F on operating will completely open and remain open.

• The body and lid are aluminium with the body having a Low-Friction coating to prevent the lid sticking.

• The lid is red for easy emergency observation.

SPECIFICATIONS

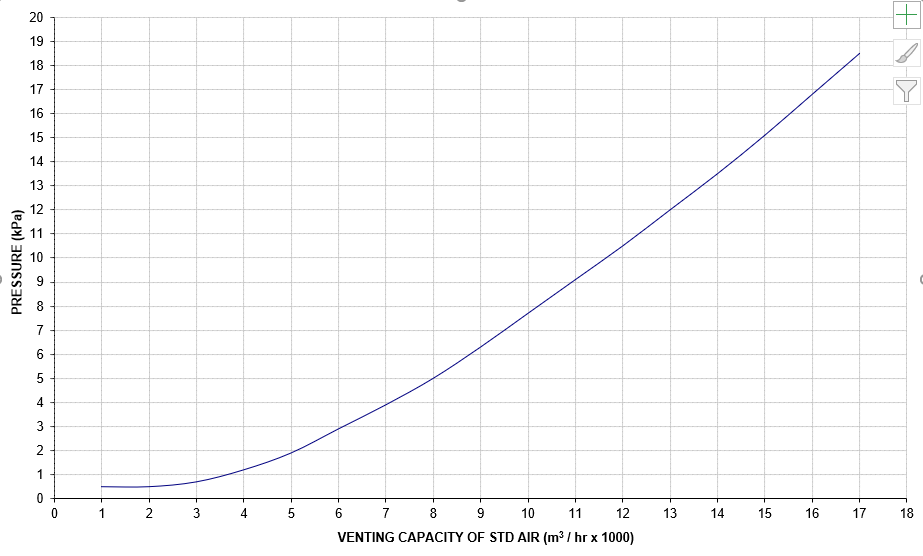

Emergency vent comes in three emergency relief settings being 17.5kPa, 24kPa and 45kPa.

Vents can be fitted to a 6” ASA 125 flange, however, we recommend the use of the 202SSF flange adaptor.

Relief capacity of 15,850m3/hr at 17.5kPa. (The 202F has to be manually reset after operating)

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)