- Tank Truck Equipment

- Service Station Equipment

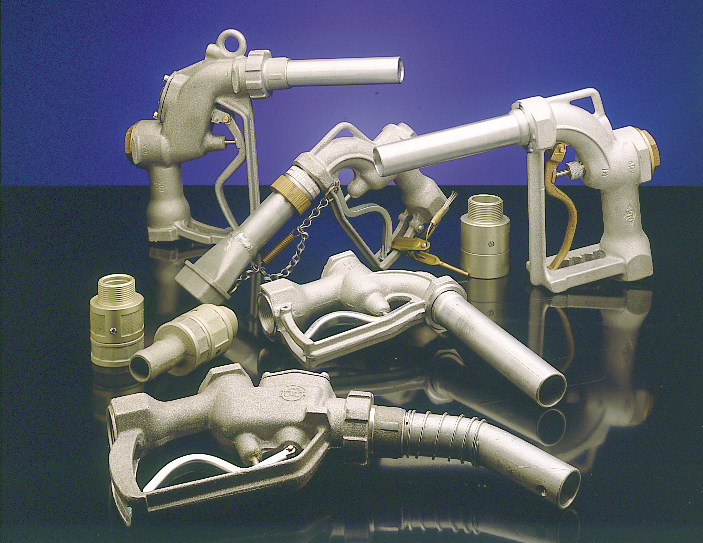

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

Dip & Fill Identity Markers

| Order codes | Spares |

|

67F - F refers to a Fill marker 67D - D refers to a Dip Marker V - refers to Vapour

|

67SD box 100

|

APPLICATION

Dip and fill marker are used to identify each fill and dip point on underground tank installations at typical service station sites. Identification is via product code and colour on the outer ring and tank number on the inner disc.

The use of such markers reduces the possibility of a product being inadvertently dropped into the incorrect product tank.

FEATURES

• Identity markers are made up of an outer product ring and inner tank identification disc. The markers comply with A.I.P recommended practice.

• All product rings are colour coded to meet A.I.P recommended practice.

• All tank number discs have an inlaid product identity lettering.

• Markers are available for all common hydrocarbon products and special unique branding can also be ordered.

• All tank outer ring and centre discs have an inlaid identity lettering or number and are UV and colour stabilized for extended life.

• The inlaid design eliminates the identification being worn away in comparison to raised lettering identity markers.

• Markers are easily secured to the driveway via epoxy adhesive combined with the 67SD fasteners (refer to installation instruction sheet).

• Shure Drive Fasteners are available in boxes of 100

SPECIFICATIONS

Varoius models and colours for DIP and FILL

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)