- Tank Truck Equipment

- Service Station Equipment

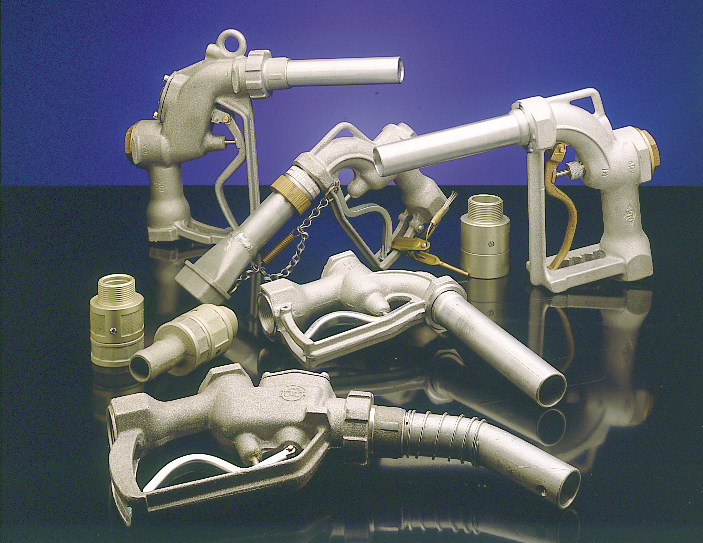

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

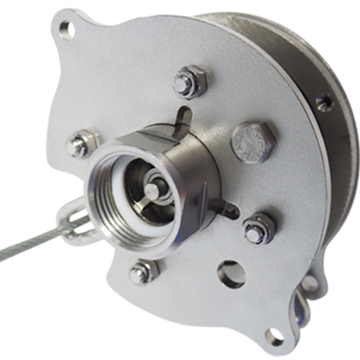

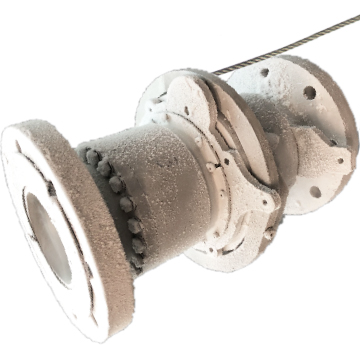

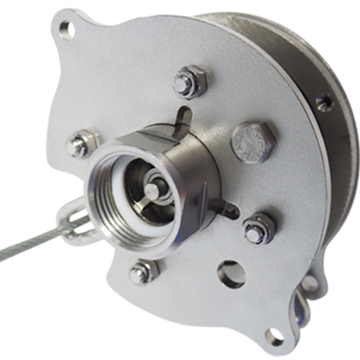

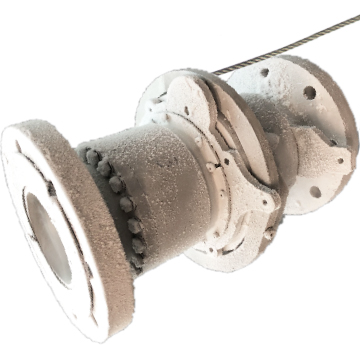

Breakaway

| Order codes | Spares |

|

NTS-SZ NTS-PU NTS-PI NTS-SZ-TT NTS-SZ-CS NTS-PU-M NTS-MPC |

Fully serviceable, kits available - call for details

|

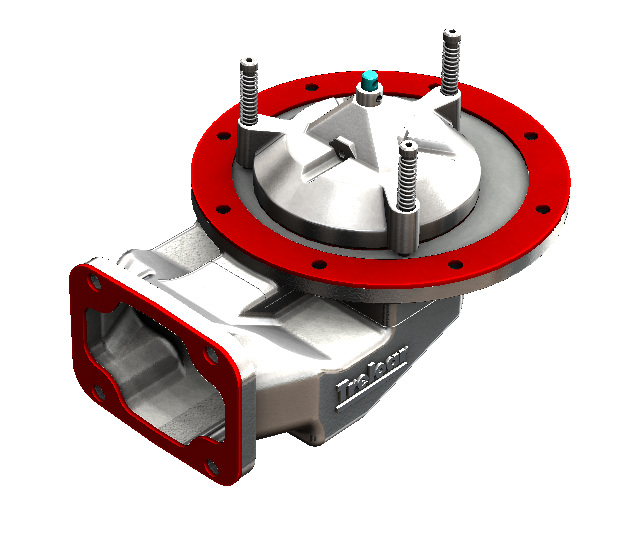

BREAKAWAY VALVE APPLICATION

Our Emergency Disconnect Safety Systems, also known as Breakaway Couplings or Breakaways, are safety systems that ensure the safe transfer of media in suction and discharge lines.

If a dangerous situation occurs, for example due to the sudden departure of a tanker truck which is still connected to a hose line, the Breakaway ensures a safe and spill-free separation of the vehicle from the system. In this manner, the ARTA Emergency Disconnect Safety System protects both the environment and the user.

ARTA Emergency Disconnect Safety Systems are used in the transport of liquid, gaseous and solid media, and they can be used on both hoses and piping. All ARTA breakaway couplings or breakaway valves can be quickly and easily reassembled without the need for replacement parts. Limitless applications and specific products for Marine, Petroleum, cryogenics, gasses, chemicals and aggressive media.

FEATURES

Any sudden impact on the line during refuelling could create a situation that is hazardous. There are many causes for such a potential impact, such as the sudden departure of a tanker connected to the coupling. ARTA’s NTS emergency disconnect safety system is recommended specifically for this reason. If an unintentional impact occurs on a line where the NTS is installed, both coupling halves will disconnect in a controlled manner, and the valves on either side will immediately close. No dangerous media will spill, and both the environment and the operator will remain safe.

SPECIFICATIONS

Sizes: DN15 (1/2“) bis DN200 (8“)

Pressure rating: PN16 (232psi) bis PN40 (580psi)

Temperature range: -55°C (-67°F) bis +200°C (+392°F)

Body material: Stainless steel 1.4301/1.4404/1.4571, Hastelloy®

Sealing: PFTE, EPDM, Viton® and other seals on request.

Connections: Thread-NPT, BSP, ISO; Flanges-ANSI, ISO; others on request

Conformities: 2014/68/EU Druckgeräterichtlinie, 2014/34/EU ATEX, EN14432, 21 CRF Part 11, USP Code 6

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)