- Tank Truck Equipment

- Service Station Equipment

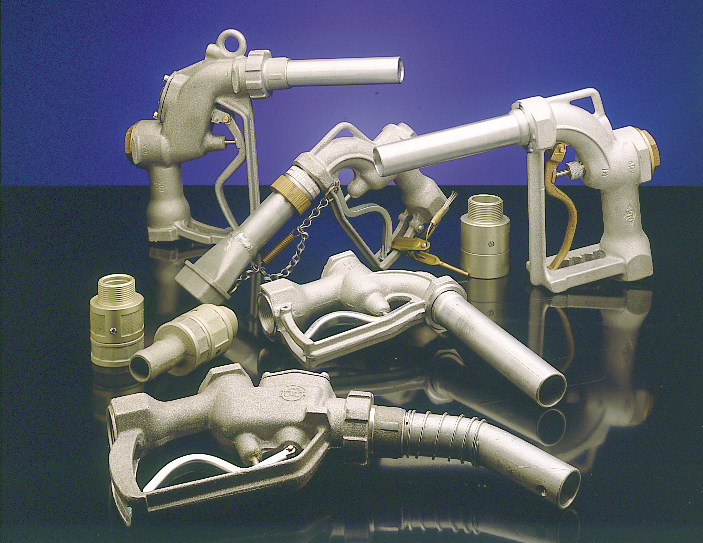

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

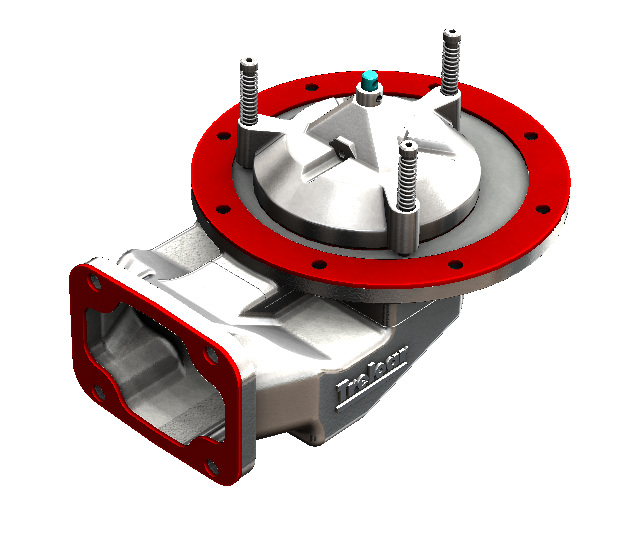

Anti-Siphon Valve

| Order codes | Spares |

|

99ASV-2150 99ASV-2200 99ASV-3150 99ASV-3200

|

The OPW 99ASV contains no adjustable, replaceable, or repairable parts.

|

APPLICATION

The OPW 99ASV anti-siphon valve is designed to automatically shut off flow of product in the event the line is broken. This feature helps prevent fuel spillage and fire hazards.

All 99ASV anti-siphon valves are equipped with a pressure relief valve, to relieve thermal expansion. They are available in 40mm and 50mm NPT sizes, smaller sizes available on request. Two different hydrostatic head pressure settings are stocked: 3m and 4.5m - other settings also available on request.

Complies with AS 1940-1993.

FEATURES

The 99ASV is recommended to be installed on the top of the Above Ground Tank. See the attached recommended installation, the A measurement from the top of the tank to the lowest point of the fuel supply line is critical for the correct selection of the anti-siphon valve. We recommend the combination of the 99ASV with a 10BM under pump shear valve for maximum protection from fuel spillage

SPECIFICATIONS

99ASV-2150: Anti-siphon Valve 40mm x 3m

99ASV-2200: Anti-siphon Valve 50mm x 3m

99ASV-3150: Anti-siphon Valve 40mm x 4.5m

99ASV-3200: Anti-siphon Valve 50mm x 4.5m

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)