- Tank Truck Equipment

- Service Station Equipment

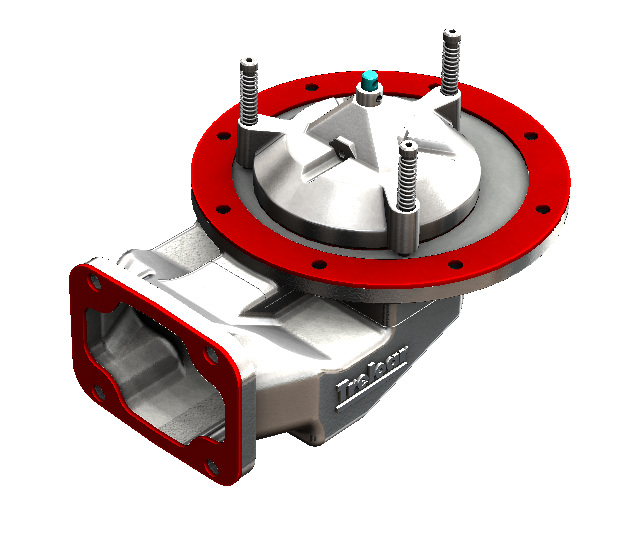

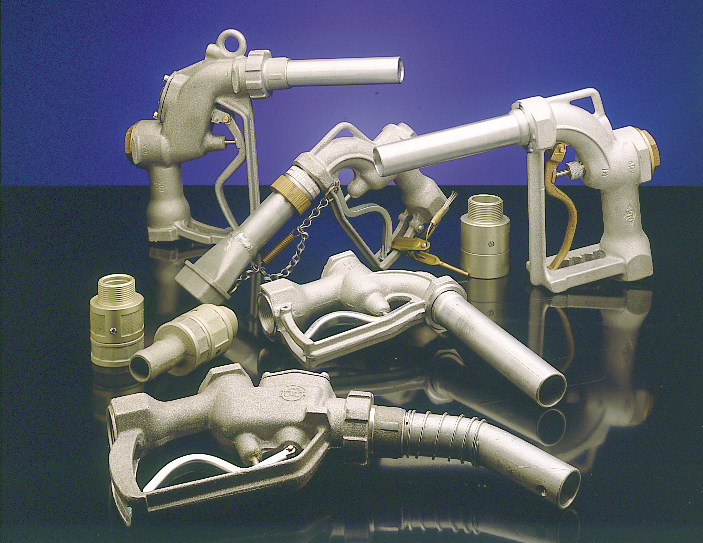

- Nozzles & Dispensing Equipment

- Terminal & Depot Equipment

- Fluid Transfer Fittings

- Valve Products

- Projects

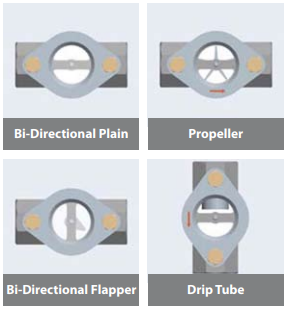

Visi flow

| Order codes | Spares |

|

1400 - Standard 1500 - Hi-pressure

|

|

APPLICATION

A quick, reliable and inexpensive way to verify flow rate and direction & monitor colour and clarity in fluid lines.

Dollar for dollar, sight flow indicators are the most cost efficient and effective way to visually monitor the flow of fluids and to determine where, if any, problems exist at certain points along the industrial process line. Applications include:

Chemical industry, power plants, petroleum industry, waste water treatment, manufacturing and OEM Markets.

FEATURES

Easy Access bolt on design:

VISI-FLO’s® unique bolt-on design fastens the face plate assembly directly to the body with no special torqueing sequence. This provides quick, complete access to the unit from the front side, which gives companies the flexibility to install VISI-FLO® in locations where other sight flow indicators cannot be installed due to clearance problems. Tie rod design sight flow indicators present challenges when it comes to fastening the lens and seal to the body.

No Leak guarantee:

Due principally to the failure of conventional flat seals, the complaint most often registered against sight flow indicators is that they leak. VISI-FLO® is guaranteed not to leak for three full years under normal use. The key design attributes that enable OPW’s innovative radial sealing design is so good, it’s guaranteed not to leak!

Maintenance-Free Design:

Visi-Flo’s unique, bolt-on-body design requires no special maintenance or torqueing sequence be followed to prevent leaks. This results in a safer, more reliable sight flow indicator than units using tie rods to fasten lens and seal to body.

SPECIFICATIONS

Sizes: 1/4" to 12"

Body Material: Carbon Steel, Bronze, 316 Stainless Steel, Ductile iron

Pressure: Up to 600PSI

Seals: Viton, Nitrile, Neoprene, EPT, Teflon, FFKM

Connection: Threaded or flanged

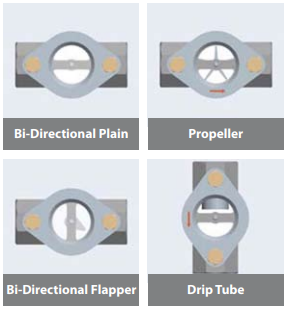

Four Indicator Styles:

• Propeller – The best way to show flow of opaque liquids. Ideal for observation at a distance. Flow from right to left is standard. Specify if left to right flow is needed. Not recommended for flow rates above 100 GPM.

• Bi-Directional Flapper – This indicator points in either direction to show you at a glance which way the liquid is flowing.

• Bi-Directional Plain – When the colour and clarity of your liquid are of prime importance.

• Drip Tube – Ideal for gravity, extremely low or intermittent flow. Keeps product from dripping on the glass. Assures constant see-through for vertical lines.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)