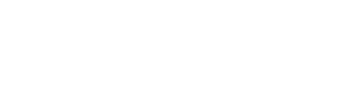

adjustable folding stairs

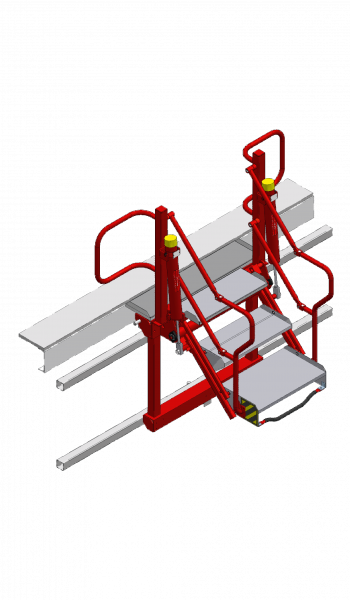

drawbridge

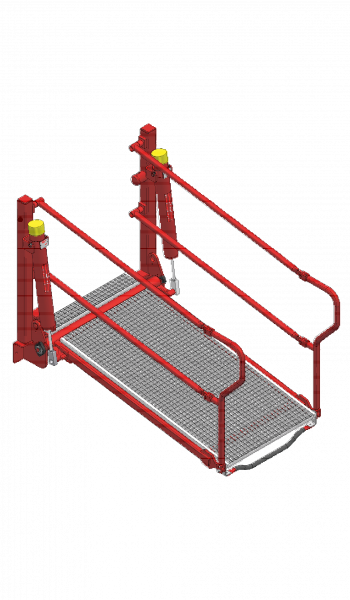

standard folding stairs

FOLDING STAIRS

Folding stairs provide a straightforward and safe access to the top of the tankers, rail cars or any other variable height platform the operator might wish to reach.

To create a safe working area, the folding stair can be fitted with a safety cage. Folding stairs for trucks with a larger step width not only increase the access to the working area, but they are also suitable for carrying and positioning of the loading arms or other equipment.

The folding stairs differentiate themselves through their robust construction and the built-in safety measures, such as anti-skid and anti-jam provisions.

- Stepwidth: 800 to 3500 mm

- No. of steps: 2 to 6

- Material: carbon steel (galvanised or coated), stainless steel

- Control: manual, pneumatic, hydraulic

- Options: parking detection, chain locking device, safety cage

- System types available include variable height platforms, adjustable safety cage and folding stairs.

Our strong working relationship with WLT allows us to provide custom solutions for you, there is virtually no limit as to what we can customise and achieve for our clients.

Dependable Products, Safe Solutions

We proudly supply WLT safe access systems, they are a European leader in the industry and produce standard designs that work for most of the folding stairs for trucks and tanker access we see here in Australia.Folding Stairs Enquiry

Fill out the form below and a member of our team will be in touch soon to discuss your requirements.

.png?width=217&height=65&name=Logo%20(2).png)

.jpg)